BAKERY

Bakery and bakery products industries are sectors with high demands in chain technology. We offer perfectly designed products that take into account critical facts such as hygiene instructions, different temperature ranges, high precision and oxidation resistance.

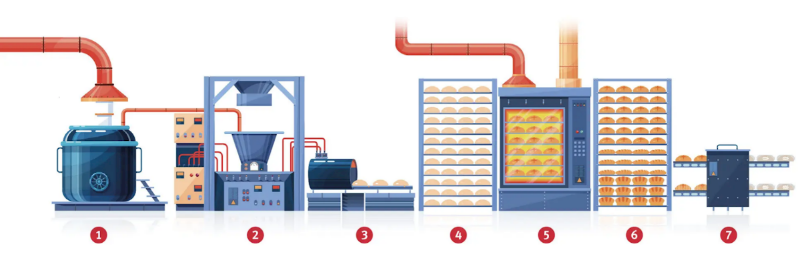

Our product range includes drive and transport chains for the entire process from dough production to fermentation and packaging of the finished product.

Our products indicated below are used in relation to the numbers in the picture.

1. STORAGE OF RAW MATERIALS

- Bushed transport chains,

- Attachment roller chains.

2. DOUGH MANUFACTURING

- Maintenance-free roller chains,

- Coated roller chains,

- Stainless steel chains,

- Oxidation resistant chains.

3. PROCESSING THE DOUGH

- Maintenance-free roller chains,

- Coated roller chains,

- stainless steel chains,

- Oxidation resistant chains,

- Link band chains.

4. RESTING THE DOUGH

- Maintenance-free roller chains,

- Coated roller chains,

- Stainless steel chains,

- Oxidation resistant chains,

- Bushed transport chains,

- Chains with hole pins.

5. BAKING

- Bushed transport chains,

- Attachment roller chains.

6. CONVEYOR EQUIPMENT

- Roller chains,

- Maintenance-free stainless steel chains.

7. PACkAGING OF BAKERY PRODUCTS

- Gripper chains,

- Pod band chains,

- Radial driven curved chains,

- Roller chains,

- Maintenance-free stainless steel chains.

Important Points:

- Increase in productivity,

- Reduced machine downtimes.

- Maximum possible length precision and tolerances in double working parts,

- Use of the most appropriate lubricant,

- On-site customer care by Tosyalı Makina personnel.

We see ourselves as a developer partner and technology leader who helps you with your challenges. Ultra-modern simulation and design tools developed in-house help our development engineers select the right products for you in advance.